HOME

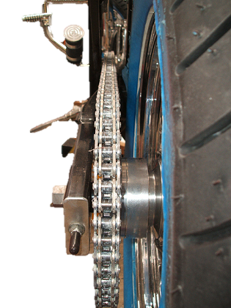

The final drive assembly is what I consider to be the transmission pulley, final drive belt, rear pulley. The Scout and Spirit used a 130 tooth belt by 1.5 inches wide. The Power plus used a 136 tooth belt by 1.5" wide. For those who like chain drive conversions, We offer them as well. When adjusting the final drive belt, keep in mind the tension should be check while adjust the belt to ride in the middle of the rear pulley. If you do not have a belt tension gage, adjust the belt so there is approximately 9/16 of belt deflection when being pressed in the middle of the bottom side of the belt. Having it to tight can cause premature wear on the wheel bearings. Like wise if the belt is too loose, the belt will skip teeth on the rear pulley and can cause the belt to fail.

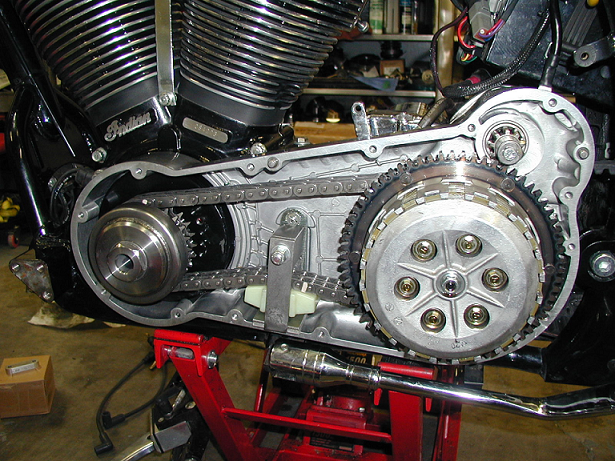

The primary drive assembly which is everything else between the engine and the transmission. True to the V-Twin design of separation of the sections, i.e. engine, primary drive and clutch/transmission. With in this unit resides the crank shaft output to the outer clutch basket assembly by an dual roll chain. Gilroy Indians used both types. Dry clutch and wet clutch systems. The early Gilory bike used this system. In 1999 to 2000, Indian moved on to the wet clutch setup in 2001. Maintenance for this unit is generally fluid changes every 5,000 miles for the wet clutch system and chain adjustment. Dry clutch inspection of the belt and pulleys. Now that these bike are getting long in age, the primary chain replacement should be considered when the miles get to 30,000. There are after-market "Automatic Chain Tensioner" available that work well in keeping the chain in order. We sell Hayden units that we modify for the inner primary and they work well. The Indian wet primary inner cover is curved in the back so we modify the unit to fit the profile.

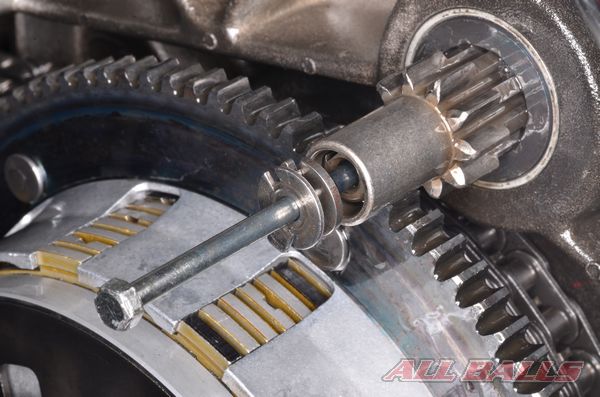

The component pictured left shows the starter jack-shaft components. This is responsible for turning the engine over from the starter motor. Areas to inspect include the small gear know as the pinion gear. and the back side of the starter ring gear mounted on the outer clutch hub. Over time the tooth engagement edges can become blunt over time causing the pinion gear the chatter by not being able to make a clean gear mesh.

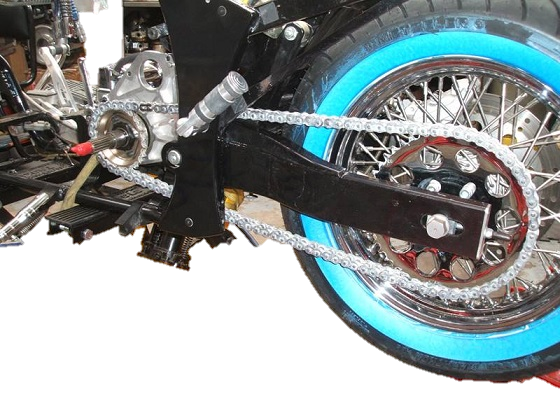

We sell chain conversion kit for the Scout, Spirit and Chief models too. IF you want to install a robust final drive setup, then the chain drive is recommended. It will require frequent adjustment when it is new and replacement at 12,000 miles. If you wait to long, you will have to replace the front and rear sprockets as the teeth of both will become elongated and prematurely wear out the new chain. See Pictures below for examples of the chain drive system.

Pictured left, primary drive components; compensator drive unit on crankshaft, Automatic chain tensioner and wet clutch assembly. A good upgrade to this clutch system is made by Barnett Performance. We sell the upgrade kit which includes performance spring set, Kevlar clutches and a new set of steel plates.

We offer chain conversion kit for the Scout, Spirit and Chief models too. If you like the 'Old School" and have a desire to change, we can discuss them. We can suggest a variety of gear ratios for your riding. Like the belt, the final drive chain requires adjustment too. I would suggest checking the chain adjustment every 1,500 to 2,000 miles. A chain does stretch. By keeping it clean and lubricated extends the life of the chain. Unlike a belt, rather than adjusting for tension of the chain, we are setting up the chain slack. The main items are alignment of the sprockets on the transmission and rear wheel. Just like a belt drive, when the rear wheel spins smoothly in a forward direction, an the belt tension is correct it will be smooth ride. For the chain drive you want about 1.00 to 1.25 inch. Push up on center of the chain (lower links and check the chain slack there. Things to look for if you have it to tight. If you experience a noise and or binding when you load the rear suspension. If it's to loose, it will have a oscillating sound. In both cases, the alignment and tension are critical for handling and component life.